So, what exactly are heavy-duty control panels? Simply put, they’re robust electrical panels that house the controls for various industrial operations, and they’re built to handle higher loads and tougher conditions. Much like how a smartphone can connect to various accessories, these control panels interact with machines and systems to keep everything running smoothly—whether it’s an assembly line in a factory or a series of outdoor lighting systems. If you’ve ever had to replace a remote for your garage door opener, you know how important it is for everything to be in sync. Control panels work on a similar principle—they need to be set up just right to ensure the entire system operates safely and effectively.

Now, let’s dive into the nitty-gritty of heavy-duty control panels, how they work, and what you need to know if you’re just getting started.

What is a Heavy-Duty Control Panel?

Heavy-duty control panels are essential components in industrial settings. They control and monitor equipment and machinery while enduring tough environmental conditions. Picture them as the central command for various operations, able to handle high voltage and higher amperage applications.

Constructed from durable materials, these panels are equipped with components that can resist dust, moisture, and extreme temperatures. This makes them ideal for factories, outdoor environments, and other challenging settings. Think of heavy-duty control panels as the sturdy vehicles that transport goods across rugged terrain—they need to be tough and reliable.

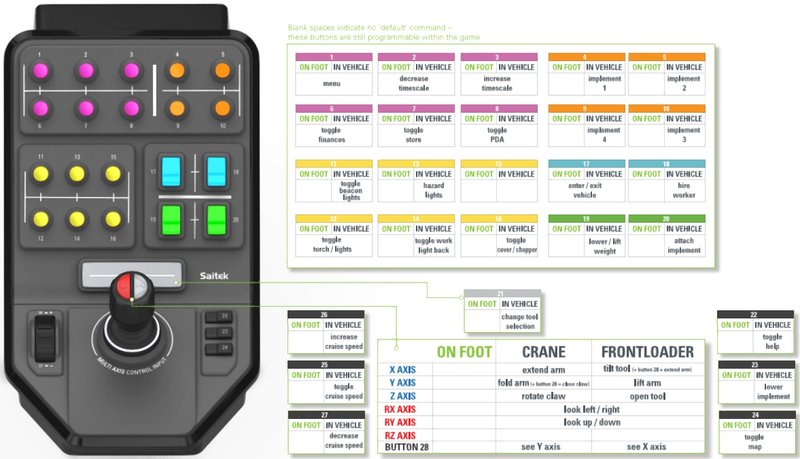

Typically, you’ll find various input and output devices in these control panels. This might include buttons, switches, displays, and even connections for remote control systems. It’s essential to understand these components if you plan to work with heavy-duty panels, as they dictate how the panel interacts with other equipment.

Components of Heavy-Duty Control Panels

Heavy-duty control panels consist of several key components, each playing an essential role in functionality. Let’s break down a few of the main parts you’ll encounter as you dig deeper into this topic.

- Enclosure: This is the outer shell that protects internal components. It’s made from tough materials like steel or aluminum to withstand harsh environments.

- Power Supply: This provides the necessary voltage and current for the panel’s operation. Think of it as the lifeblood that powers the entire system.

- Control Equipment: This includes all the switches, buttons, and relays that allow you to operate machines effectively. These components are the main point of interaction.

- Indicators: Lights or displays that provide real-time information about the panel’s status. They’re like warning lights in a car, alerting you to potential issues.

Each of these components works in harmony to create a cohesive control system. Fractions of a second can make all the difference in industrial applications, making reliability and speed critical.

How Do Heavy-Duty Control Panels Work?

Understanding the functionality of heavy-duty control panels might seem overwhelming, but it’s all about how components interact to manage electrical signals. When operators push buttons or flip switches, they send signals to the control equipment, telling it what to do—whether that’s turning something on, adjusting power levels, or shutting down a system in an emergency.

When a command is given, the control panel processes the signal and communicates with connected machines. This could involve activating motors, adjusting alarms, or synchronizing with other control panels. Imagine this like a symphony; each instrument (or machine) needs to be in tune and playing at the right time for the piece to sound great.

One essential aspect to note is feedback systems. Many heavy-duty panels are equipped with sensors that provide real-time feedback. This can inform operators if something isn’t functioning well. It’s similar to how the check engine light in your car keeps you informed about potential mechanical issues before they escalate into bigger problems.

Benefits of Heavy-Duty Control Panels

Investing in heavy-duty control panels offers numerous advantages for industrial operations. Here’s why these panels are worth considering:

- Durability: Built to last, they resist harsh weather and wear and tear, ensuring long-term functionality.

- Efficiency: They streamline operations by allowing for better control and monitoring, enhancing productivity.

- Safety: Incorporating features like emergency stop buttons and alarms improves safety for all personnel.

- Customization: Most heavy-duty control panels can be tailored to meet specific needs, making them versatile for various applications.

With these benefits in mind, it’s clear why heavy-duty control panels are critical in managing industrial processes effectively.

Common Troubleshooting Tips for Heavy-Duty Control Panels

Just like any piece of equipment, heavy-duty control panels can run into issues. If something goes wrong, you’ll want to troubleshoot effectively. Here are some practical steps you can take:

- Check Connections: Sometimes, a loose connection can cause major issues. Ensure all wires and components are securely connected.

- Inspect for Damage: Look for any signs of wear or damage, particularly on the enclosure or internal components. Any sign of physical damage should be addressed immediately.

- Review the Manual: The instruction manual will often have specific troubleshooting steps for your model, helping you pinpoint the issue.

- Reset the System: Sometimes, you just need to reset the panel. This can clear temporary faults and restore normal operation.

By following these troubleshooting tips, you’ll be better equipped to handle any hiccups in your operations confidently.

Diving into the world of heavy-duty control panels might seem like a lot at first, but remember, you’re starting to learn how these powerful tools work to keep industrial operations running smoothly. They are the backbone of many systems, and having a good grasp on their components and functionality can make a big difference.

So, whether you’re looking to install a new panel or simply understand how they function, I hope this guide offers clarity. With a little patience and exploration, you can master heavy-duty control panels, bringing you one step closer to being confident in managing industrial processes.